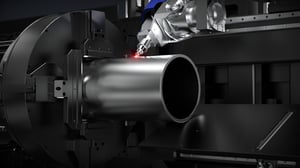

THE FIBER TUBE XL

LASER TUBE CUTTING MACHINE, FULLY AUTOMATED.

The Fiber TUBE XL tube laser delivers unmatched power, precision, and efficiency for industrial tube and profile cutting. Designed for large diameters and high-production demands, it features advanced technology, high-speed processing, and superior reliability. Whether cutting round, square, or complex profiles, it ensures maximum performance, precision, and versatility for heavy-duty applications.

Pipe

HSS

Angle

Channel

H-Beam

UP TO 25" DIAMETER

CORE FEATURES

3D CONTOUR BEVEL HEAD

The TUBE XL bevel cutting head is designed to handle multi-axis movement, making them ideal for complex cuts on round, square, and rectangular profiles. The slim profile allows access to previously impossible profiles.

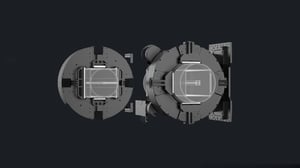

ADAPTATIVE CLAMPING FOR ALL PROFILES

The Fiber TUBE XL features an adaptive clamping system that automatically adjusts for round, square, rectangular, oval, and custom profiles. Other industry leading features are available, like high speed rotation and clamping, self-centering and pipe position detection.

TRIPLE CHUCK SYSTEM - ZERO TAIL CUTTING

The 3-chuck design provides superior stability and precision, minimizing vibration, ensuring perfect alignment, and reducing material waste—making it ideal for high-speed, high-accuracy industrial tube cutting. It also enables zero tail cutting, for close to no material waste.

ROBUST AND VERSATILE frame design

The Fiber Tube XL features a durable, reinforced frame, manufactured with a high precision manufacturing process to give it the strength and dynamic performance necessary to process large tubes and profiles at high speed.

ADVANCED SERVO-DRIVEN SUPPORTS

The advanced servo-driven active supports dynamically adjust with high sensitivity, guaranteeing stable movement and precise cutting.

Smart Control - intelligent & Intuitive

Large touchscreen controller provides easy operation. Features include tested parameters for all cutting processes including bevel, remote monitoring, and intelligent path nesting.

.webp?width=300&name=machitech-controller%20(1).webp)

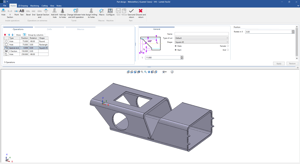

Lantek Flex3D Nesting Software

Our tube laser machines are optimized for Lantek Flex3D, combining advanced nesting, intelligent path optimization, and full 3D cutting capabilities with high-speed precision. Lantek’s automation and adaptive parameter management enhance efficiency, while the Fiber TUBE XL ensures seamless, accurate cuts on round, square, and complex profiles.

Show more

- Thick Wall Capabilities - from 6kW to 12kW Laser Sources

- Durable Construction - Designed for 24/7 Operation

- Multi-Process - Cutting, Marking and Beveling in a Single Operation

- Reinforced Frame - Built for processing up to 6600 lbs tubes

- Adaptative Clamping - Automatically Adjusts for Different Profiles

- 3D Capabilities - The Optional Bevel Head Alows for Complex 3D Cuts

- Focus Compensation - Automatically Adjusts Laser Focus Height

- Short Chain Unloading - Automated Unloading of Longer Profiles

- Short Tail Unloading - Automated Support to Collect Shorter Cut Parts

- CNC Controller - Touch Screen Controller w/ Remote Management

- Lantek Flex 3D - Industry Leading Nesting Software for 3D profiles

- Full Process Database - Integrated and Tested Parameters/Cut Charts

ON-SITE BY SPECIALISTS

INSTALLATION AND TRAINING

FOR THE LIFE OF THE MACHINE

UNLIMITED REMOTE SUPPORT

AVAILABLE WHEN YOU NEED

LARGEST SUPPORT NETWORK

INCLUDED WITH THIS MACHINE

MACHINE SPECIFICATIONS

MODELS

40' L - 14" Ø

40' L - 19" Ø

40' L - 25" Ø

OPERATIONAL DATA

Processing Range

0.8" - 13.2" (20 - 350 mm)

2.2" - 19.7" (60 - 500 mm)

3" - 24.8" (80 - 630 mm)

Max. Profile Length

40' (12 m)

40' (12 m)

40' (12 m)

Laser Power

6, 12 KW

6, 12 KW

6, 12 KW

Linear Load Capacity

68 lb/ft (100 kg/m)

135 lb/ft (200 kg/m)

170 lb/ft (250 kg/m)

Workpiece Weight

2650 lbs (1200 kg)

5300 lbs (2400 kg)

6600 lbs (3000 kg)

Max. Positioning Speed

148 ft/min (45 m/min)

148 ft/min (45 m/min)

148 ft/min (45 m/min)

Chuck Rotation Speed

75 rpm

45 rpm

45 rpm

Number of Chucks

3

3

4

3D Bevel Capabilities

Optional

Optional

Optional

MACHINE DIMENSIONS

Total Length

Based on 40' unloading length. 20' and 30' unloading also available.

105' (32 m)

105' (32 m)

105' (32 m)

Total Width

26' (8 m)

29' (9 m)

32' (10 m)

Total Height

12.5' (3.8 m)

12.5' (3.8 m)

12.5' (3.8 m)

Machine Weight

This corresponds to the machine weight with standard equipment (12m unloading). Does not include the laser source, chiller and dust collector.

66100 lbs (30000 kg)

75000 lbs (34000 kg)

85000 lbs (38500 kg)

Show more

LEADERS IN HIGH POWER

CUTTING TECHNOLOGY

A suite of advanced cutting technologies for optimal speed, quality, efficiency, and precision.ZERO-CONTACT HEIGHT TRACKING

Sensors monitor surface distance, adjusting nozzle height for optimal focal point.+ NOZZLE LIFE & PRECISION

INTELLIGENT BEAM COOLING

Optimizes beam shape by cooling the optics and gases for improved laser performance.+ EFFICIENCY & LIFESPAN

SPEEDFOCUS™ CUTTING PROCESS

A cutting method that maintains a negative focus for optimal speeds.+ CUT SPEEDS

QUALITYFOCUS™ CUTTING PROCESS

A cutting method that maintains a positive focus for optimal finish quality.+ FINISH QUALITY

INTEGRATED HEAD GAS MIXING

Integrated Gas Mixing at the head allows for near instant changes made to the gases at the material.+ RESPONSE & ACCURACY

LOW GAS PRESSURE CUTTING

A specialized nozzle and gas flow refine the beam, improving airflow and reducing pressure.+ EFFICIENCY & GAS SAVINGS

ACTIVE DUAL FOCUS COMPENSATION

Real time detection and compensation of focal point deviations.+ QUALITY & RELIABILITY

DYNAMIC PUNCH PIERCE

Equipped with sensors that optimize piercing in the shortest times possible.+ SPEED & GAS SAVINGS

REQUEST A QUOTE

Ready to receive a quote for your project? Fill the form below or contact one of our specialists at 888-988-7220.